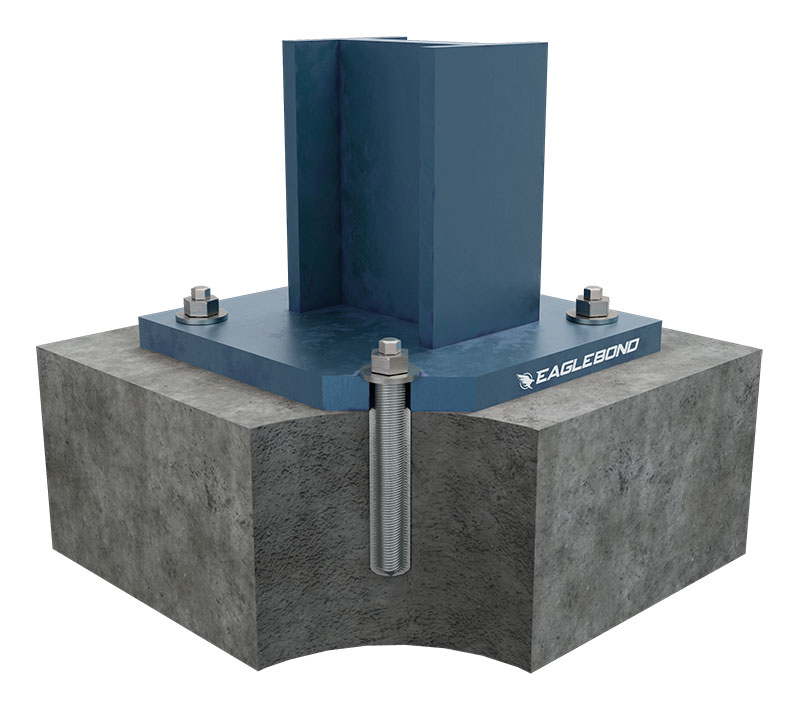

AnchorBond500 Concrete Anchor Epoxy is a super strong fixing and reinforcing solution for rebar and threaded rod heavy-duty structural anchoring connections.

Approved for use with post-installed threaded rod and rebar connection to cracked and non-cracked concrete with class C20/25 to C50/60 AnchorBond500 concrete anchoring epoxy is primarily used for the post-installation of anchor bolts. It features an epoxy agent with strong adhesive properties for bonding and securing loads to concrete by using rebar, bolts, rods, and dowels. This epoxy solution offers exceptionally high and ultimate bonding strength. It is the ideal choice for heavy loads, vibration resistance, and harsh environmental conditions.

| Ambient temperature (°C) | -5°C | 0°C | 15°C | ≥25°C |

| Operable time (min) | 120 | 60 | 45 | 25 |

| Curing time (h) | 72 | 48 | 24 | 12 |

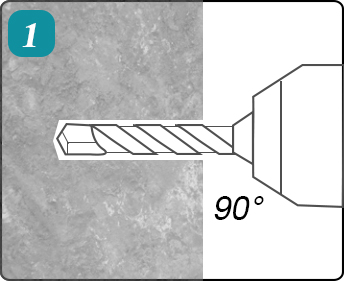

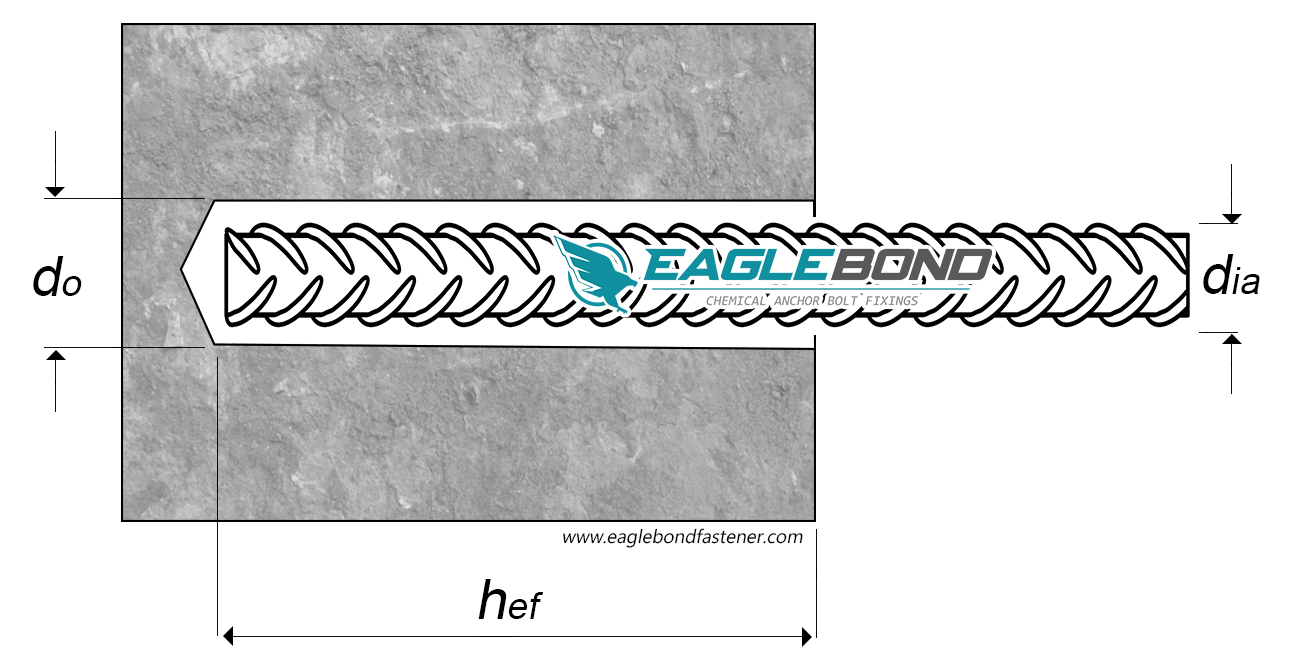

Drill the hole according to the specified diameter and anchoring depth provided in the technical data sheet to ensure that the anticipated load strength requirements are met.

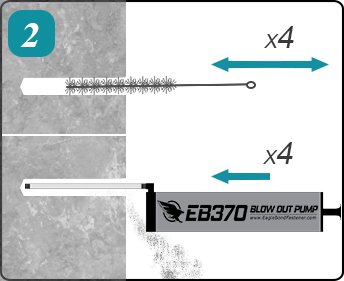

Ensure that the drilled hole is properly cleaned before injecting the chemical adhesive to avoid compromising the strength of the bond. Use steel brush and EB370 Industrial Blow Out Pump to clean debris and repeat the cleaning process at least 4 to 5 times.

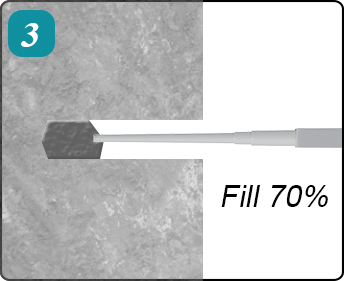

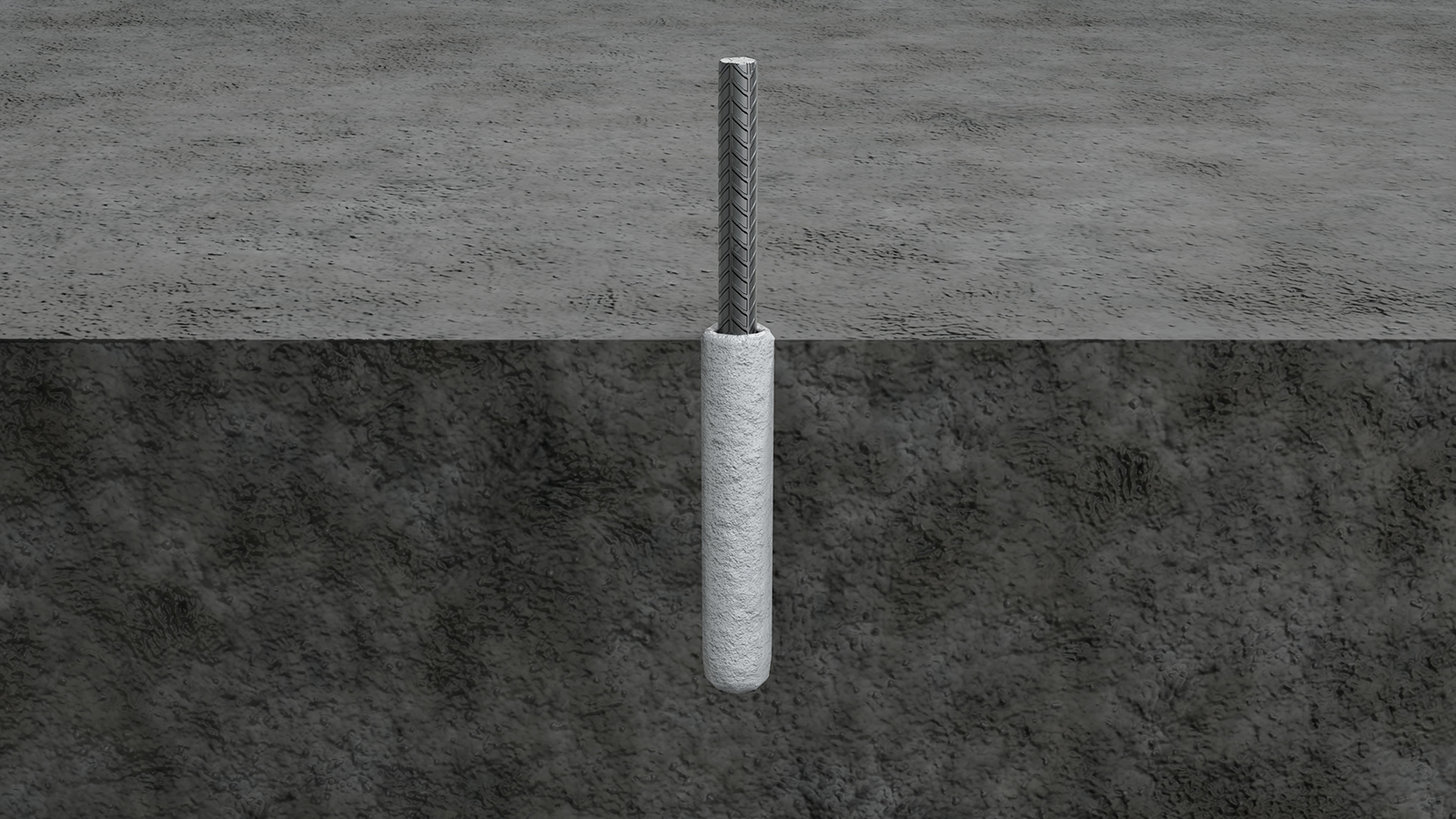

EagleBond AB500 Concrete Epoxy features a specialized static mixer and dispenser. It is advisable to inject approximately 70% or 2/3 of the adhesive volume relative to the hole's depth.

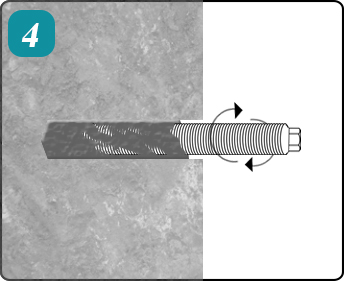

It is recommended to use markers on the steel bar or threaded rod to indicate the appropriate depth for embedding the anchor. Gently and steadily insert the steel bar or threaded rod in a single direction until it reaches the bottom of the drilled hole.

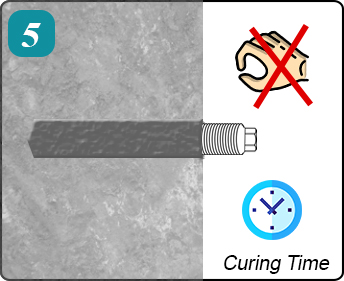

During curing time, Avoid moving the steel bar or bolt and refrain from applying load.

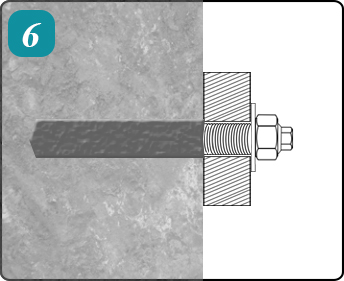

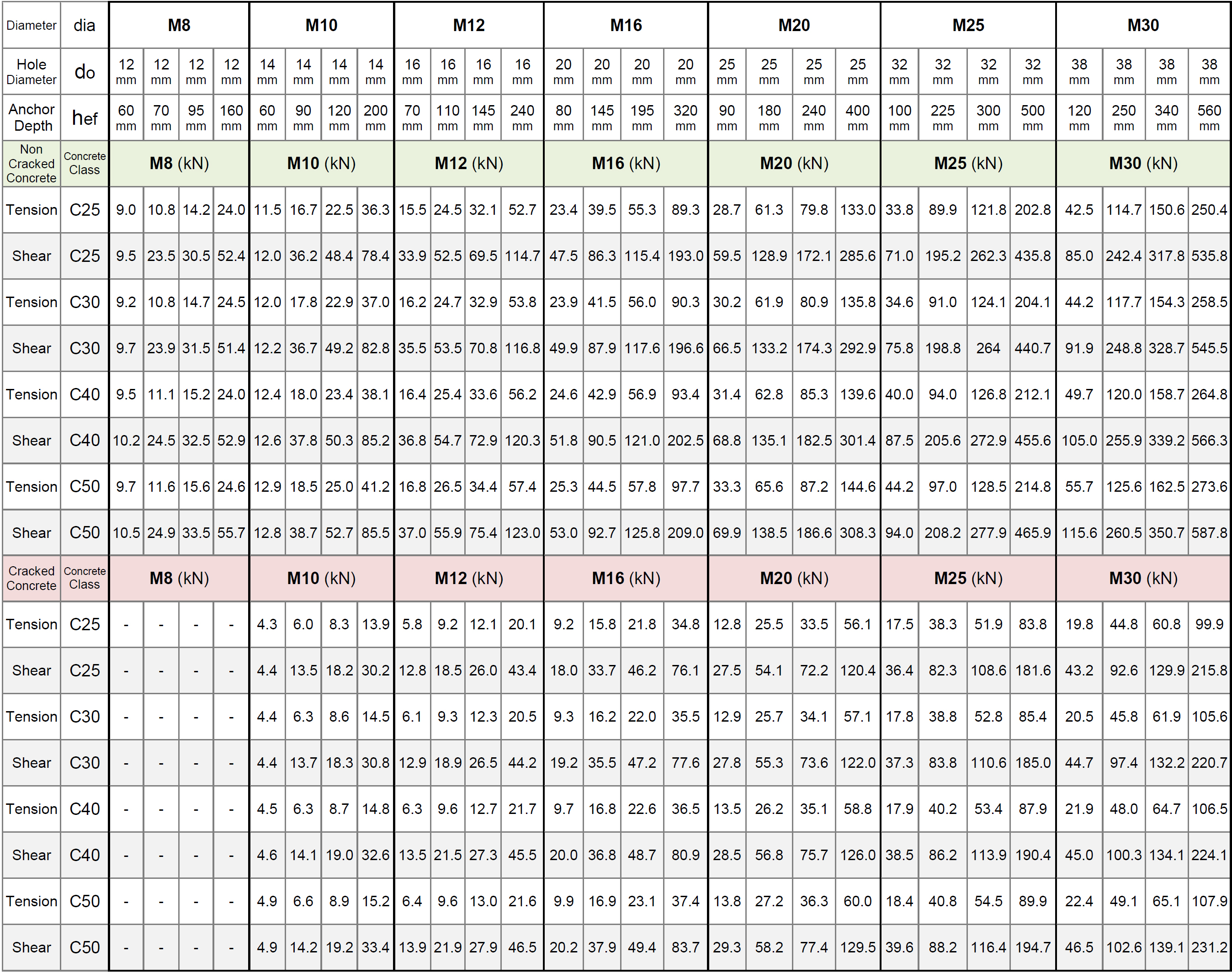

For recommended safety load, Please check the Anchoring Load Capacity Chart.

| Tensile Strength (ASTM D638) | ≥55 MPa | ≥7977 psi |

| Compressive Strength (ASTM D695) | ≥82 MPa | ≥12,000 psi |

| Compressive Modulus (ASTM D695) | ≥3500 MPa | - |

| Bending Strength | ≥50MPa | ≥7252 psi |

| Splitting Strength | ≥8.5MPa | ≥1233 psi |

| Elongation at Break (ASTM D638) | 1.4% | - |

| Deflection Temperature (ASTM D648) | ≥65℃ | - |

| Viscosity of Mixture | 18-22Pa•S | - |

| Density after Curing | 1.5±0.1g/cm^3 | - |

| Thixotropy Index | ≥4.0 | - |

| Chemical Substances | Concrete admixtures |

| Diesel oil | |

| Petrol | |

| Construction solvents | |

| Concrete form release oil | |

| Marine environment water | |

| Deionized water | |

| Salt spray corrosion test | |

| Environmental Substances | |

| Alkaline | Concrete drilling mud |

| Concrete potash solution | |

| Solvents | Xylene (mixture) |

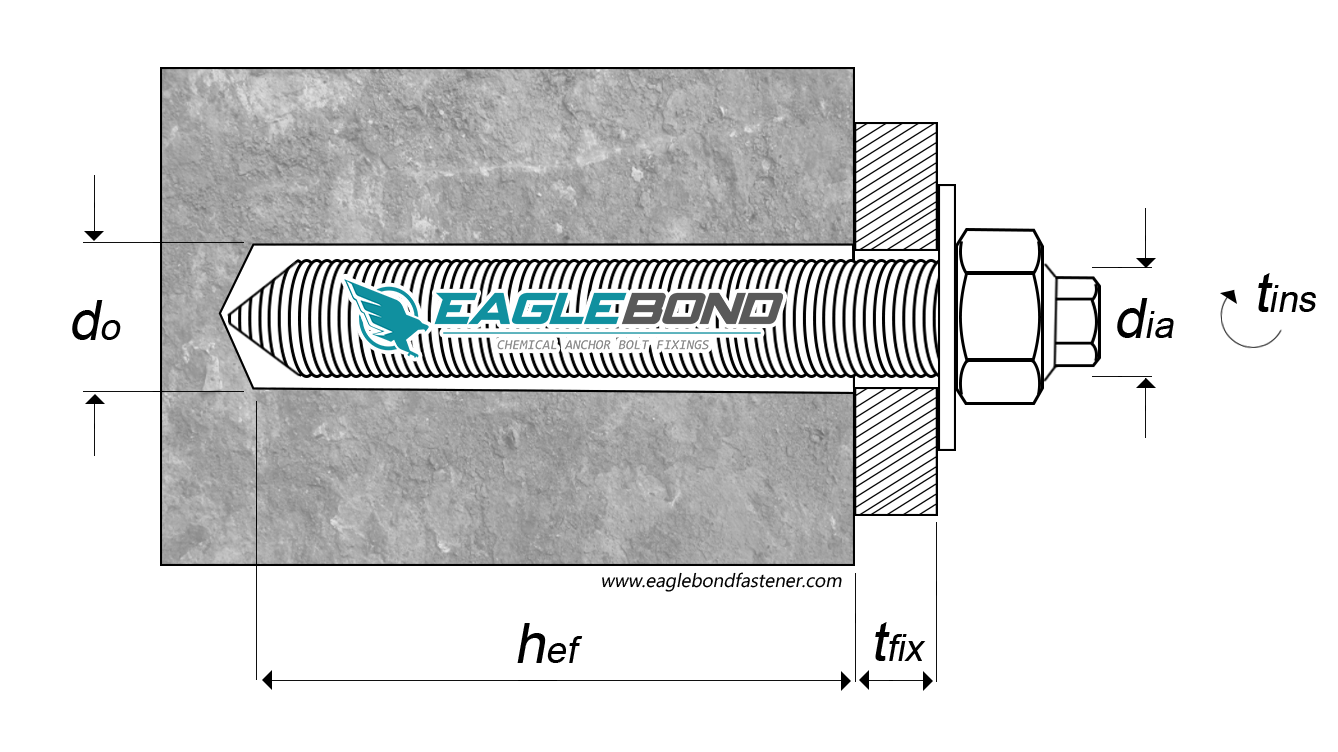

| Diameter | dia | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|---|

| Hole Diameter | do | mm | 10 | 12 | 14 | 18 | 24 | 28 | 35 |

| Anchoring Depth | hef | mm | 80 | 90 | 110 | 125 | 170 | 210 | 280 |

| Max Torque | Tins | Nm | 10 | 20 | 40 | 80 | 120 | 150 | 300 |

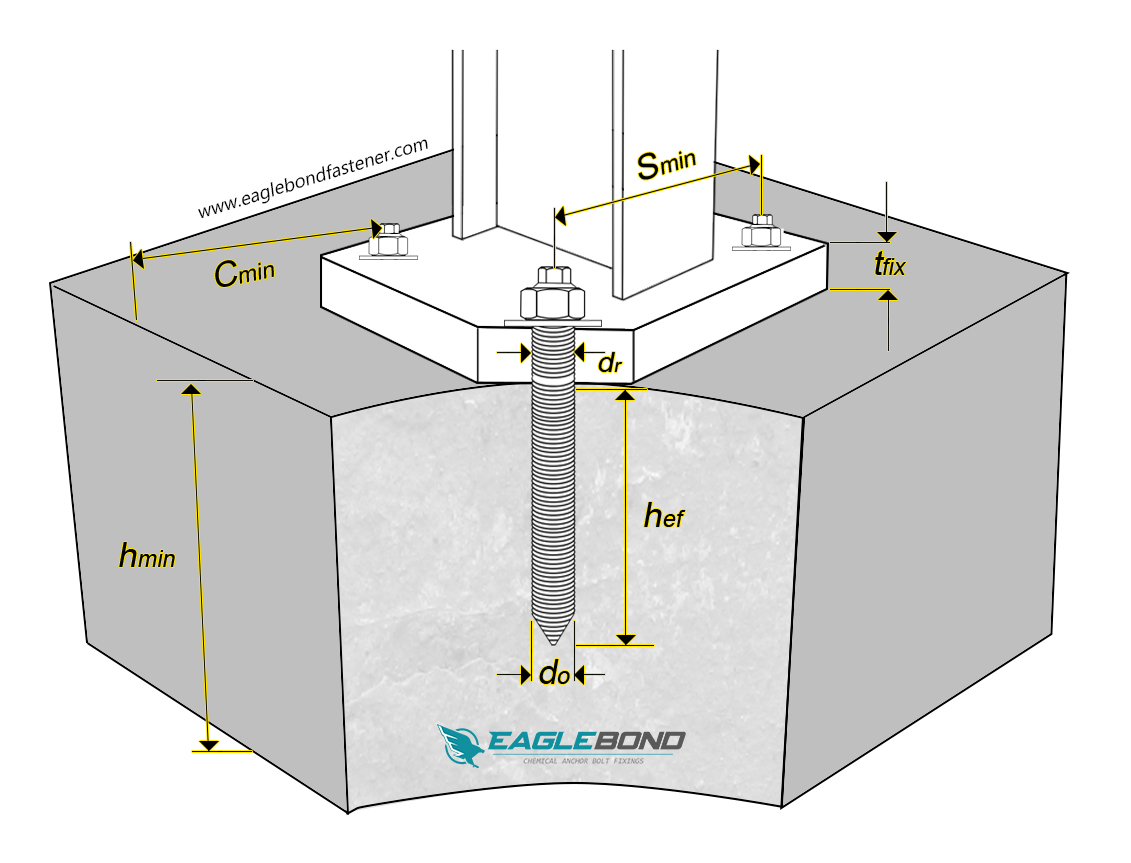

| Minimum Thickness of Concrete | hmin | mm | 110 | 120 | 140 | 160 | 220 | 260 | 330 |

| Minimum Spacing for Bolt | Smin | mm | 40 | 45 | 55 | 65 | 85 | 105 | 140 |

| Minimum Edge Distance | Cmin | mm | 40 | 45 | 55 | 65 | 85 | 105 | 140 |

| Fixture Hole Diameter | dr | mm | 9 | 12 | 14 | 18 | 22 | 26 | 33 |

| Fixture Max Thickness | tfix | mm | 20 | 25 | 30 | 40 | 50 | 65 | 70 |

| Non-Cracked Concrete | Bolt Grade | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|---|

| Tension | G4.8 | kN | 10.0 | 13.5 | 20.5 | 32.8 | 41.0 | 61.5 | 82.8 |

| Shear | G4.8 | kN | 7.5 | 9.0 | 14.3 | 27.0 | 37.6 | 54.5 | 78.0 |

| Tension | G8.8 | kN | 10.3 | 14.2 | 21.2 | 34.3 | 48.5 | 66.5 | 87.8 |

| Shear | G8.8 | kN | 10.4 | 13.3 | 22.1 | 42.8 | 59.4 | 79.7 | 101.0 |

| Tension | ss304 | kN | 10.1 | 13.7 | 20.9 | 34.3 | 46.5 | 63.5 | 86.3 |

| Shear | ss304 | kN | 9.6 | 10.5 | 15.8 | 29.3 | 39.4 | 58.2 | 80.0 |

| Cracked Concrete | Bolt Grade | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|---|

| Tension | G4.8 | kN | 6.2 | 8.2 | 9.5 | 11.5 | 20.3 | 26.0 | 36.8 |

| Shear | G4.8 | kN | 5.3 | 7.8 | 11.5 | 19.0 | 29.0 | 44.9 | 72.0 |

| Tension | G8.8 | kN | 6.4 | 8.5 | 10.9 | 12.8 | 22.8 | 29.5 | 37.4 |

| Shear | G8.8 | kN | 8.2 | 10.9 | 19.6 | 35.5 | 44.0 | 62.7 | 91.5 |

| Tension | ss304 | kN | 6.3 | 8.4 | 9.8 | 12.6 | 21.4 | 26.3 | 37.4 |

| Shear | ss304 | kN | 5.4 | 8.9 | 11.7 | 19.2 | 32.0 | 45.7 | 72.5 |

Note: The Safety Load Estimation typically represents approximately one-half to one-third of the actual Ultimate Strength *Increasing the diameter and anchoring depth of the drilled hole will proportionately increase the recommended safety load

Note: The Safety Load Estimation typically represents approximately one-half to one-third of the actual Ultimate Strength *1 kilonewton (kN) is approximately equal to 101.97 kilograms (kg)

| Diameter Φ(mm) |

Hole Diameter Φ(mm) |

Anchoring Strength Reference (kN) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 13 | 26 | 27 | 27 | 28 | ||||||||||||||

| 12 | 16 | 37 | 38 | 38 | 39 | ||||||||||||||

| 14 | 18 | 46 | 48 | 50 | 52 | 54 | |||||||||||||

| 16 | 20 | 60 | 68 | 68 | 68 | 69 | |||||||||||||

| 18 | 22 | 75 | 83 | 84 | 85 | 85 | |||||||||||||

| 20 | 25 | 95 | 100 | 100 | 100 | 105 | |||||||||||||

| 22 | 28 | 115 | 128 | 128 | 128 | 128 | |||||||||||||

| 25 | 32 | 145 | 160 | 160 | 162 | 165 | 165 | ||||||||||||

| 28 | 35 | 176 | 195 | 205 | 205 | 205 | 205 | ||||||||||||

| 32 | 40 | 240 | 245 | 245 | 260 | 270 | |||||||||||||

| 40 | 50 | 310 | 370 | 405 | 420 | 422 | |||||||||||||

| Anchoring Depth | 80 | 90 | 100 | 110 | 120 | 135 | 150 | 160 | 180 | 200 | 220 | 240 | 250 | 270 | 305 | 350 | 400 | 440 | |

| Diameter(mm) | Hole Dia(mm) | Depth(mm) | Number of Fixings |

| M8 | 10 | 80 | 80 |

| M10 | 12 | 90 | 50 |

| M12 | 14 | 110 | 30 |

| M16 | 18 | 125 | 20 |

| M20 | 24 | 170 | 10 |

| M24 | 28 | 210 | 6 |

| M30 | 34 | 260 | 3 |

| M36 | 40 | 330 | 1 |