EagleBond chemical adhesive bolt is a type of strong fastening bolt solutions that is used in structural construction especially in fixing loads. It is a very effective fastening solution, that eliminates the risk of stress on concrete and breaking of concrete like mechanical anchor bolts produced when fastening.

Eagle Bond Chemical Anchor Bolt is a spin type anchoring system that is very easy and simple to use, No special tools are needed. Chemical Capsule anchor bolt fixing is a very fast curing adhesive and has an optimal perfomance when consistency is required.

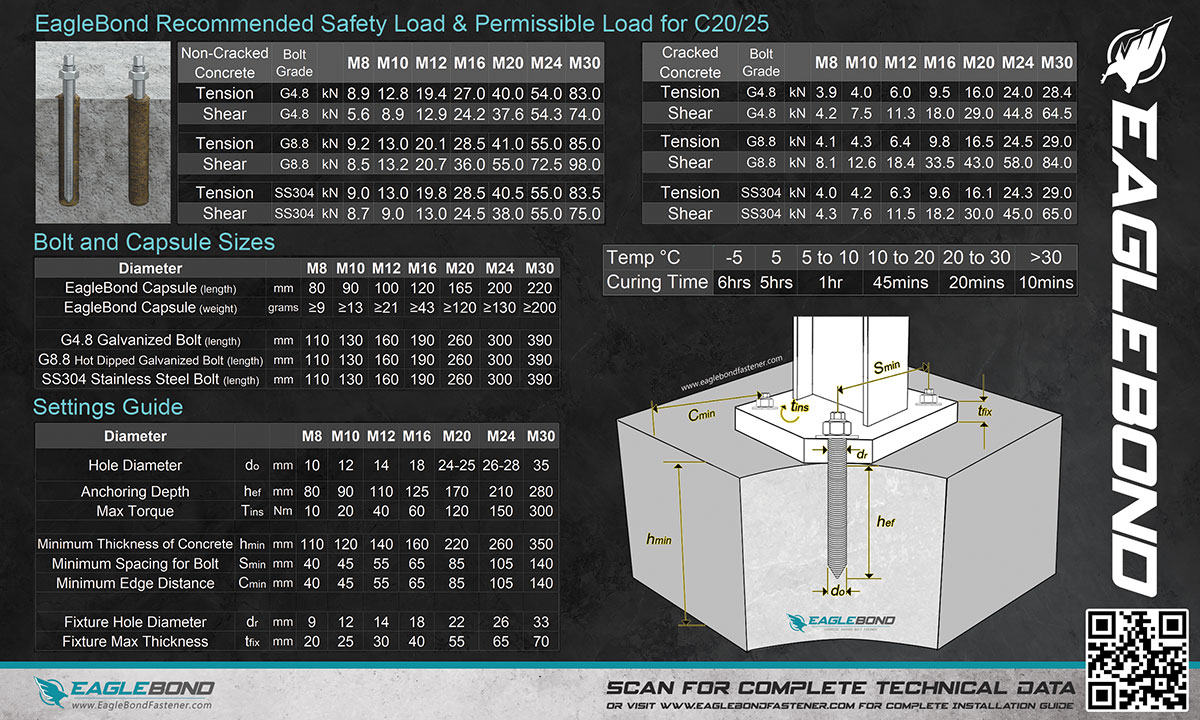

Approved for use with post-installed anchor rod to cracked and non-cracked concrete with class C20/25 to C50/60

Eagle Bond Chemical Capsule and Bolt is composed of high-strength anchor bolt, complete with nut and washer, and chemical compositions of vinyl resins, selected quartz sands and curing agents stored inside a glass capsule for stronger and easier application.

- Anchor Rod Carbon steel grade4.8 galvanized iron zinc plated (5 μm)

- Anchor Rod Carbon steel grade8.8 hot dip galvanized (45 μm)

- Anchor Rod Stainless Steel 304

- 2 component vinyl ester resin, black silica rock and curing agent in glass capsule

| Temperature (°C) | -5°C | 5°C | 5°C to 10°C | 20°C to 30°C | ≥30°C |

|---|---|---|---|---|---|

| Curing Time | 6hrs | 5hrs | 45mins | 20mins | 10mins |

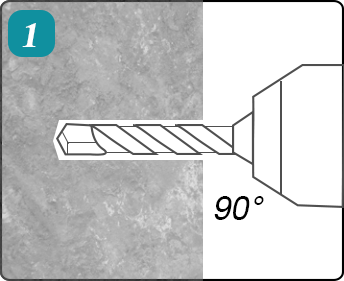

Drill the hole according to the specified diameter and anchoring depth provided in the technical data sheet to ensure that the anticipated load strength requirements are met.

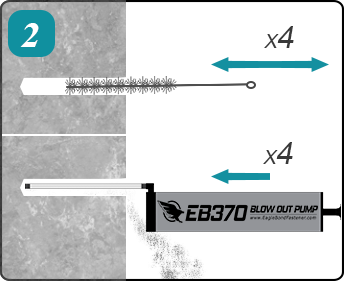

Ensure that the drilled hole is properly cleaned before inserting the capsule resin adhesive to avoid compromising the strength of the bond. Use steel brush and EB370 Industrial Blow Out Pump to clean debris and repeat the cleaning process at least 4 to 5 times.

Insert the capsule into the 90° hole and make sure that it runs smoothly when inserted to prevent breakage.

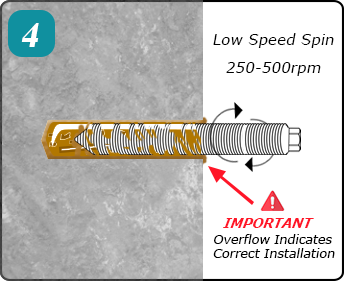

Drill the anchor rod at a low speed settings. Once the stud reaches the bottom of the hole, stop drilling immediately. Further drilling will result spillage of chemical resin contents from the hole.

IMPORTANT NOTE: If no chemical resin comes out of the hole, it indicates an incorrect installation. In such cases, remove the rod and start over using another capsule.

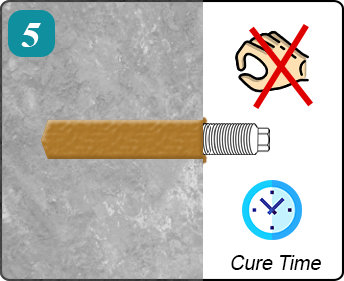

During curing time, Avoid moving the anchor bolt and refrain from applying load.

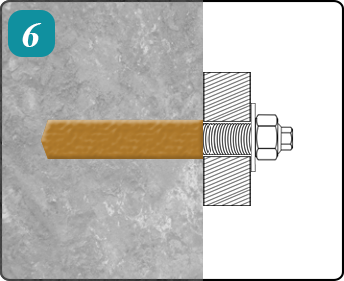

For recommended safety load, Please check the Anchoring Load Capacity Chart.

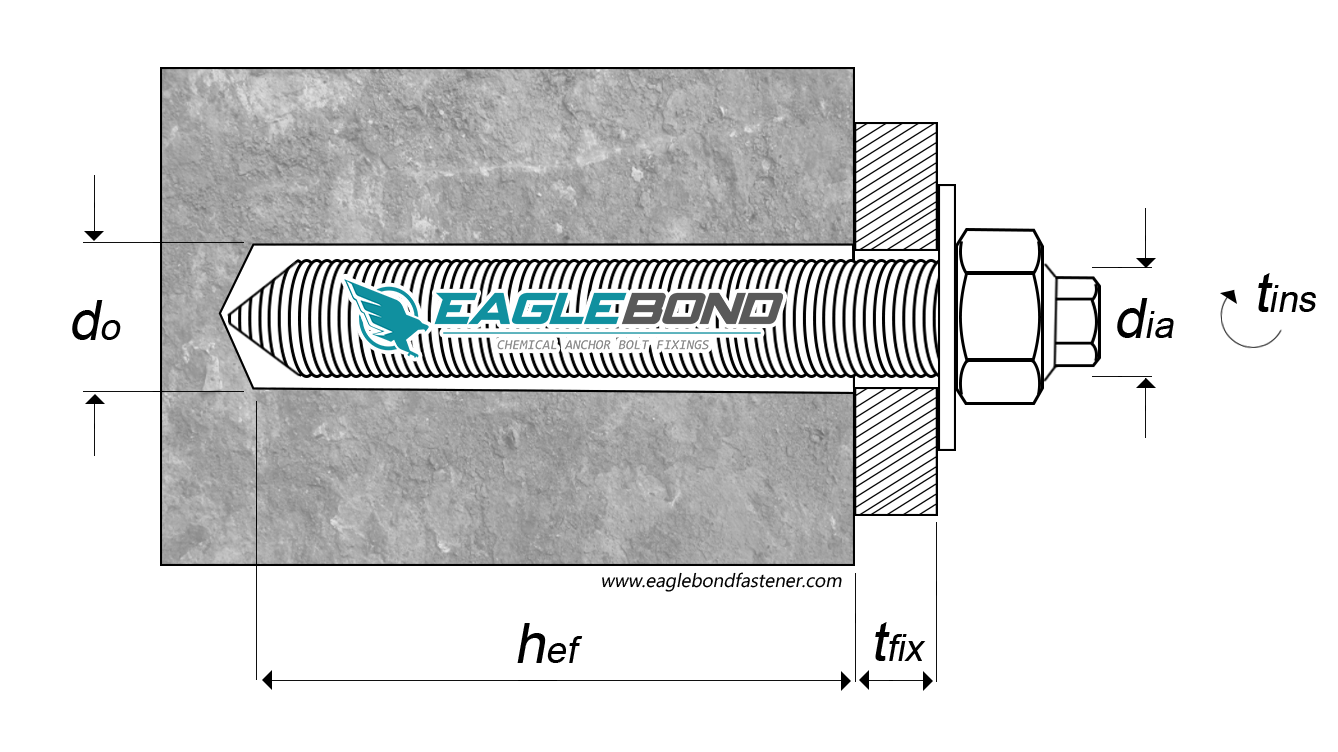

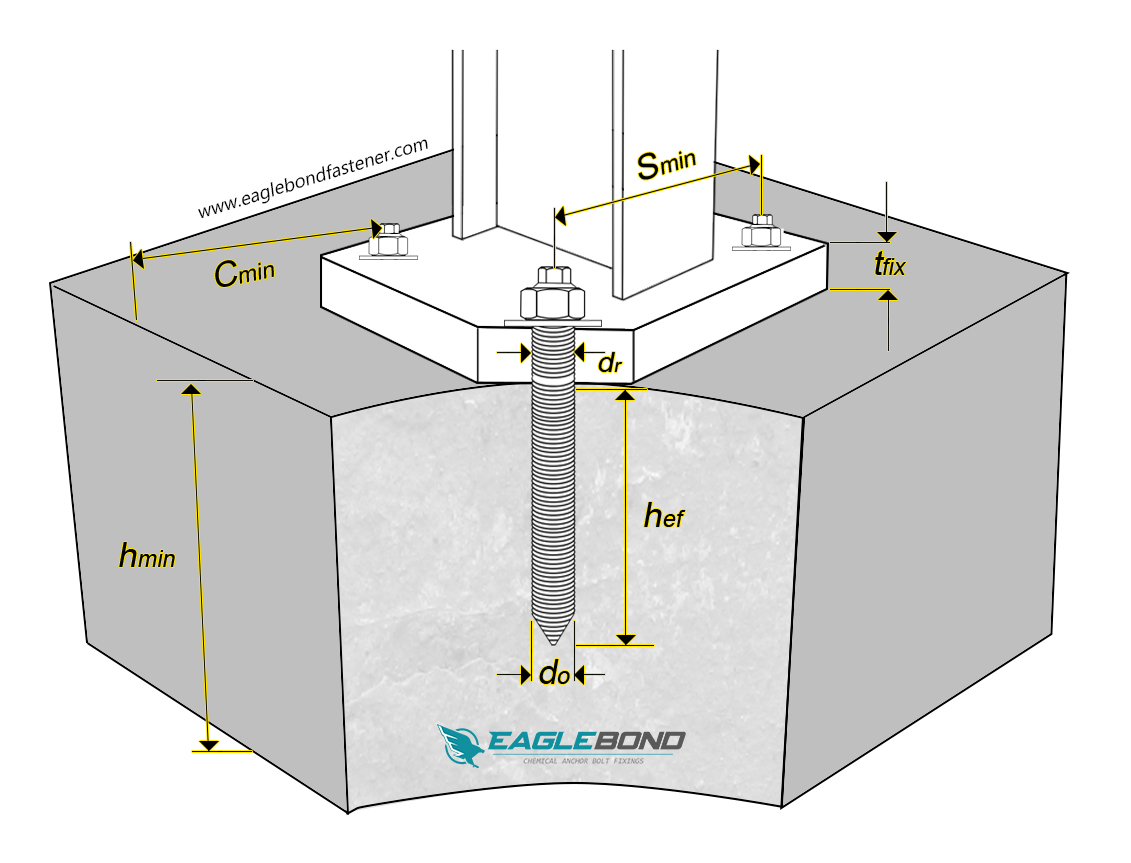

| Diameter | dia | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|---|

| Hole Diameter | do | mm | 10 | 12 | 14 | 18 | 24-25 | 26-28 | 35 |

| Anchoring Depth | hef | mm | 80 | 90 | 110 | 125 | 170 | 210 | 280 |

| Max Torque | Tins | Nm | 10 | 20 | 40 | 80 | 120 | 150 | 300 |

| Minimum Thickness of Concrete | hmin | mm | 110 | 120 | 140 | 160 | 220 | 260 | 330 |

| Minimum Spacing for Bolt | Smin | mm | 40 | 45 | 55 | 65 | 85 | 105 | 140 |

| Minimum Edge Distance | Cmin | mm | 40 | 45 | 55 | 65 | 85 | 105 | 140 |

| Fixture Hole Diameter | dr | mm | 9 | 12 | 14 | 18 | 22 | 26 | 33 |

| Fixture Max Thickness | tfix | mm | 20 | 25 | 30 | 40 | 50 | 65 | 70 |

| Non-Cracked | Bolt Grade | M8 | M10 | M12 | M16 | M20 | M24 | M30 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Result 1 | Tension | G8.8 | kN | - | 48.5 | 68.2 | 127.9 | 205.6 | 304.5 | - |

| Test Result 1 | Shear | G8.8 | kN | - | 30.9 | 41.9 | 85.9 | 129.9 | 179.8 | - |

| Test Result 2 | Tension | G8.8 | kN | - | 49.9 | 69.8 | 128.5 | 209.7 | 305.6 | - |

| Test Result 2 | Shear | G8.8 | kN | - | 29.8 | 40.8 | 85.8 | 127.8 | 178.6 | - |

| Test Result 3 | Tension | G8.8 | kN | - | 48.1 | 69.9 | 128.2 | 206.7 | 301.5 | - |

| Test Result 3 | Shear | G8.8 | kN | - | 30.2 | 41.2 | 80.2 | 124.2 | 181.2 | - |

| Test Result 4 | Tension | G8.8 | kN | - | 48.5 | 67.9 | 129.4 | 207.6 | 306.6 | - |

| Test Result 4 | Shear | G8.8 | kN | - | 29.1 | 42.1 | 84.5 | 125.5 | 180.6 | - |

| Test Result 5 | Tension | G8.8 | kN | - | 47.9 | 68.2 | 127.8 | 202.5 | 307.9 | - |

| Test Result 5 | Shear | G8.8 | kN | - | 28.5 | 41.5 | 82.5 | 127.5 | 180.9 | - |

| Non-Cracked Concrete | Bolt Grade | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|---|

| Tension | G4.8 | kN | 8.9 | 12.8 | 19.4 | 27.0 | 40.0 | 54.0 | 83.0 |

| Shear | G4.8 | kN | 5.6 | 8.9 | 12.9 | 24.2 | 37.6 | 54.3 | 74.0 |

| Tension | G8.8 | kN | 9.2 | 13.0 | 20.1 | 28.5 | 41.0 | 55.0 | 85.0 |

| Shear | G8.8 | kN | 8.5 | 13.2 | 20.7 | 36.0 | 55.0 | 72.5 | 98.0 |

| Tension | ss304 | kN | 9.0 | 13.0 | 19.8 | 28.5 | 40.5 | 55.0 | 83.5 |

| Shear | ss304 | kN | 8.7 | 9.0 | 13.0 | 24.5 | 38.0 | 55.0 | 75.0 |

| Cracked Concrete | Bolt Grade | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|---|

| Tension | G4.8 | kN | 3.9 | 4.0 | 6.0 | 9.5 | 16.0 | 24.0 | 28.4 |

| Shear | G4.8 | kN | 4.2 | 7.5 | 11.3 | 18.0 | 29.0 | 44.8 | 64.5 |

| Tension | G8.8 | kN | 4.1 | 4.3 | 6.4 | 9.8 | 16.5 | 24.5 | 29.0 |

| Shear | G8.8 | kN | 8.1 | 12.6 | 18.4 | 33.5 | 43.0 | 58.0 | 84.0 |

| Tension | ss304 | kN | 4.0 | 4.2 | 6.3 | 9.6 | 16.1 | 24.3 | 29.0 |

| Shear | ss304 | kN | 4.3 | 7.6 | 11.5 | 18.2 | 30.0 | 45.0 | 65.0 |

Note: The Safety Load Estimation typically represents approximately one-half to one-third of the actual Ultimate Strength.

| Diameter | M8 | M10 | M12 | M16 | M20 | M24 | M30 | |

|---|---|---|---|---|---|---|---|---|

| EagleBond Capsule (length) | mm | 80 | 90 | 100 | 120 | 165 | 205 | 220 |

| EagleBond Capsule (weight) | grams | ≥9 | ≥13 | ≥21 | ≥43 | ≥120 | ≥130 | ≥200 |

| G4.8 Galvanized Bolt (length) | mm | 110 | 130 | 160 | 190 | 260 | 300 | 390 |

| G8.8 Hot Dipped Galvanized Bolt (length) | mm | 110 | 130 | 160 | 190 | 260 | 300 | 390 |

| Stainless Steel SS304 Bolt (length) | mm | 110 | 130 | 160 | 190 | 260 | 300 | 390 |

| #1080 Hex Socket Adaptor Set 5mm to 13mm |

#298 EB370 Industrial Blow Out Pump / Air Pump / 370mm |

Eagle Bond SDS PLUS and SDS Max - Masonry Drill Bit Carbide 4 Tip Ø6mm to Ø40mm |

#281 & #299 Nylon Steel Brush |

|---|---|---|---|

|

|

|

|

|

Used in Standard Drill Chuck |

Used for blowing out |

Chembolt Drill Bit Sizes |

Used for brushing out |